Introduction to Filling Machines

In the modern manufacturing landscape, efficiency and precision are paramount. One of the critical components in achieving this efficiency is the use of Filling Machine Manufacturers. These machines are designed to automate the process of filling containers with products ranging from liquids to powders. Their importance spans a variety of industries, including pharmaceuticals, food and beverage, cosmetics, and chemicals. This article delves into the world of filling machines, detailing their significance, the types available, and how to choose the right manufacturer for your specific needs.

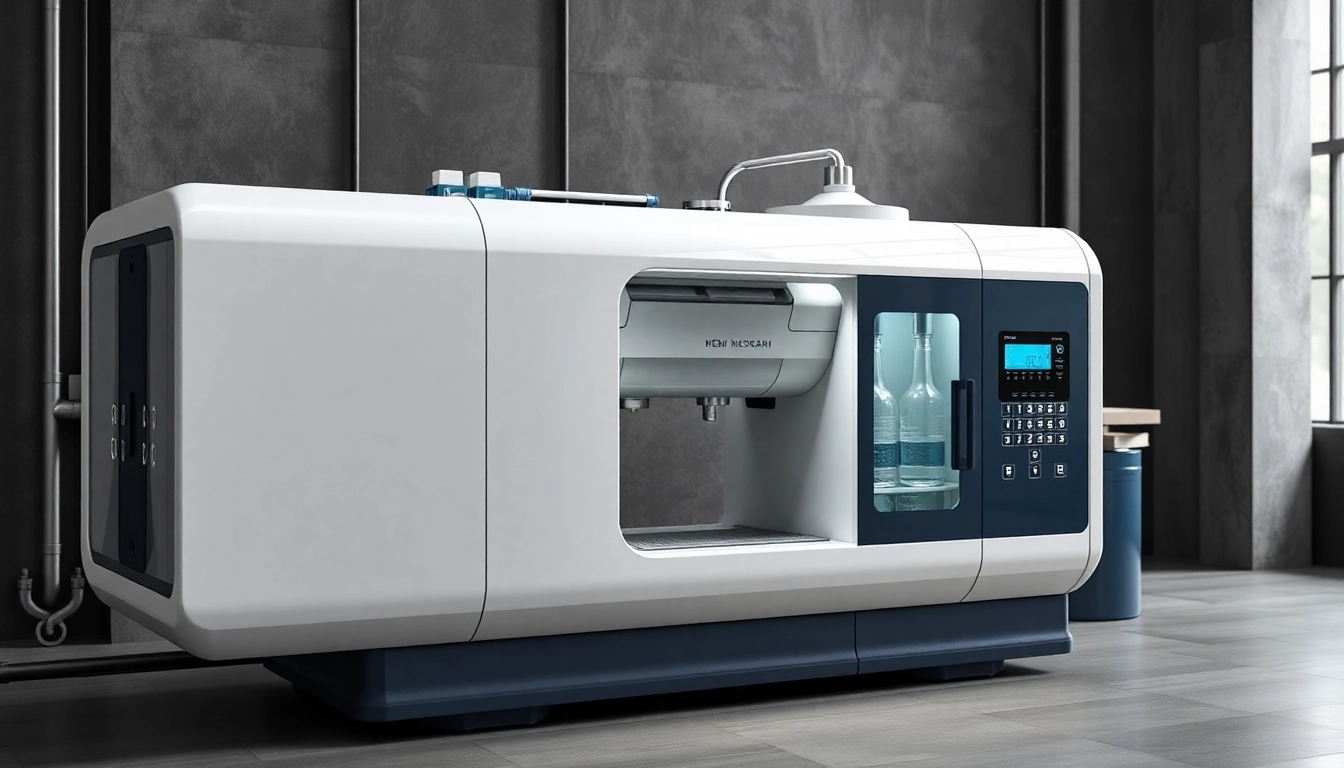

What Are Filling Machines?

Filling machines are automated devices designed to fill containers, such as bottles, jars, or pouches, with varying types of substances. These substances can range from liquids, creams, and gels to powders and granules. The primary function of a filling machine is to ensure that the correct volume of product is dispensed into each container, facilitating minimal waste and maintaining product consistency.

Importance in Various Industries

Filling machines are vital in numerous sectors due to their ability to streamline production processes and enhance accuracy in filling. In the food and beverage industry, for instance, filling machines are essential for ensuring compliance with health standards while maximizing production efficiency. In the pharmaceutical sector, precision is critical; filling machines help avoid contamination and ensure that the correct dosage is delivered. Overall, these machines contribute significantly to operational efficiency, quality assurance, and reducing labor costs across various sectors.

Types of Filling Machines

Filling machines come in various types, each designed for specific applications. Below are some of the most common filling machine types:

- Liquid Filling Machines: Best for filling liquids, such as beverages and pharmaceuticals. They can be further classified into volumetric, gravimetric, and piston filling machines.

- Powder Filling Machines: Specifically designed for powder-based products, these machines measure and fill powders with high precision.

- Semi-Automatic Filling Machines: Require some manual intervention, but enhance speed and accuracy compared to fully manual processes.

- Automatic Filling Machines: Fully automated systems that require minimal operator input, suitable for high-volume production lines.

- Cap Filling Machines: These machines not only fill containers but also cap them, closing the manufacturing cycle.

Finding Reliable Filling Machine Manufacturers

Choosing the right filling machine manufacturer is crucial to ensure that your production line runs smoothly and to meet your specific operational needs. A good manufacturer can mean the difference between efficient production and costly delays.

Key Considerations for Selection

When selecting a filling machine manufacturer, consider the following factors:

- Industry Experience: Look for manufacturers with a proven track record in your specific industry. Their experience can be invaluable in providing tailored solutions.

- Machine Customization: Ensure that the manufacturer offers customization options to meet your specific filling requirements, whether in terms of machine size, filling speed, or the types of products being filled.

- Quality Assurance: Manufacturers should adhere to strict quality standards. Compliance with ISO certifications is a good indicator of quality.

- Customer Support: A manufacturer that offers excellent customer service and technical support can help resolve issues quickly, minimizing downtime.

Evaluating Manufacturer Reputation

Researching the reputation of a manufacturer is crucial. Consider looking for:

- Reviews and Testimonials: Customer feedback can provide insights into the reliability and efficiency of the manufacturer’s products.

- Industry Recognition: Awards or recognitions within the industry can signify credibility and excellence.

- Longevity: Manufacturers that have been in business for many years often have more experience in addressing customer needs and can offer more reliable equipment.

Reviewing Customer Testimonials

Customer testimonials serve as a valuable resource when evaluating potential filling machine manufacturers. Look for reviews that detail:

- Product performance and reliability.

- How well the machines integrate with existing production lines.

- The level of customer service provided during the purchase process and afterward.

Top Filling Machine Manufacturers in the Industry

Understanding the key players in the filling machine manufacturing industry can help you make informed decisions regarding your supply chain. Here we explore some of the top filling machine manufacturers and what they offer.

Overview of Leading Brands

Several manufacturers have emerged as leaders in the industry, known for their innovative solutions and high-quality products. Here are a few notable brands:

- Accutek Packaging Equipment Company Inc.: Offers a wide variety of filling machines designed for diverse applications. Their products include gravimetric and volumetric filling systems.

- Cozzoli Machine Company: Known for liquid filling, capping, and washing machines, Cozzoli has a strong reputation for meeting custom application needs.

- Volumetric Technologies: This manufacturer specializes in bottle-filling equipment, providing reliable solutions for various industries.

- E-PAK Machinery: Offers a complete range of liquid filling machines, cappers, and labelers for bottling facilities.

- Oden Machinery: Focuses on quality filling systems, serving a diverse group of industries including food, beverage, and pharmaceuticals.

Comparison of Features and Pricing

Comparing features and pricing among the top filling machine manufacturers helps in selecting the best equipment for your operation. Factors to compare include:

- Filling Speed: Measure the speed of each machine to understand which model suits your production volume.

- Machine Dimensions: Ensure the machine fits your production space efficiently.

- Cost: While price is essential, consider the total cost of ownership, including maintenance and operation expenses.

- Warranty and Service: Compare warranty offers and the level of after-sales service provided by each manufacturer.

Case Studies of Successful Implementations

Examining case studies can illustrate the real-world benefits of specific filling machines:

- Pharmaceutical Industry: A major pharmaceutical company implemented Accutek’s piston filling machine to increase their speed by 30%, which allowed for greater production and minimized waste.

- Food & Beverage: E-PAK’s fully automatic filling and capping line improved a beverage manufacturer’s throughput by 50%, demonstrating remarkable efficiency improvements.

- Cosmetics: Cozzoli’s equipment was integrated into a cosmetic producer’s facility resulting in a 40% reduction in manual labor associated with filling processes.

Technological Advancements in Filling Machines

The filling machine industry is witnessing rapid technological advancements driven by the need for higher efficiency and flexibility. Innovations in this space are reshaping manufacturing realities.

Automation in Filling Processes

Automation is revolutionizing the filling machine landscape. Automated filling machines reduce labor-related costs and enhance accuracy. Current trends reflect:

- Integration of Robotics: Robotic arms now handle tasks like loading containers and sealing caps which increase speed and reduce human error.

- Smart Technologies: Some modern machines come equipped with sensors and IoT capabilities that allow real-time monitoring and adjustments to be made during production.

Integration with Packaging Systems

Filling machines are increasingly integrated with packaging lines for seamless production flows. Techniques include:

- Inline Systems: These systems allow products to be filled and packaged in one continuous process, minimizing handling and transfer time.

- Labeling Integration: Combining filling and labeling processes in a single machine can significantly enhance throughput and efficiency.

Future Trends in Filling Technology

The future of filling machines is bright, with several trends predicted to shape the industry:

- Sustainability: Manufacturers may focus on developing machines that reduce waste and energy consumption, addressing environmental concerns.

- Advanced Materials: The use of smart materials that allow for better product protection and shelf life is on the rise.

- Customization and Flexibility: As consumer demands shift, filling machines will evolve to offer greater flexibility to switch between product types more quickly.

Conclusion and Next Steps

In conclusion, filling machines are essential components in the manufacturing process, providing efficiency, accuracy, and versatility. By understanding what filling machines are, their importance across various industries, and how to choose the right manufacturer, businesses can significantly enhance their production operations.

Choosing the Right Machine for Your Needs

When determining which filling machine is suitable for your operations, keep in mind the specific requirements of your business, including product type, production volume, and budget constraints. Consulting with manufacturers can provide clarity on the best options available according to your specifications.

Contacting Manufacturers for Quotes

Once you have identified potential filling machine manufacturers, reach out to them for quotes. It’s advisable to request detailed specifications and recommendations based on your unique production needs.

Setting Up Your New Equipment

The final step is setting up your new filling machine on your production floor. Ensure that adequate training is provided to operators, and establish a maintenance schedule to maximize machine efficiency and lifespan.