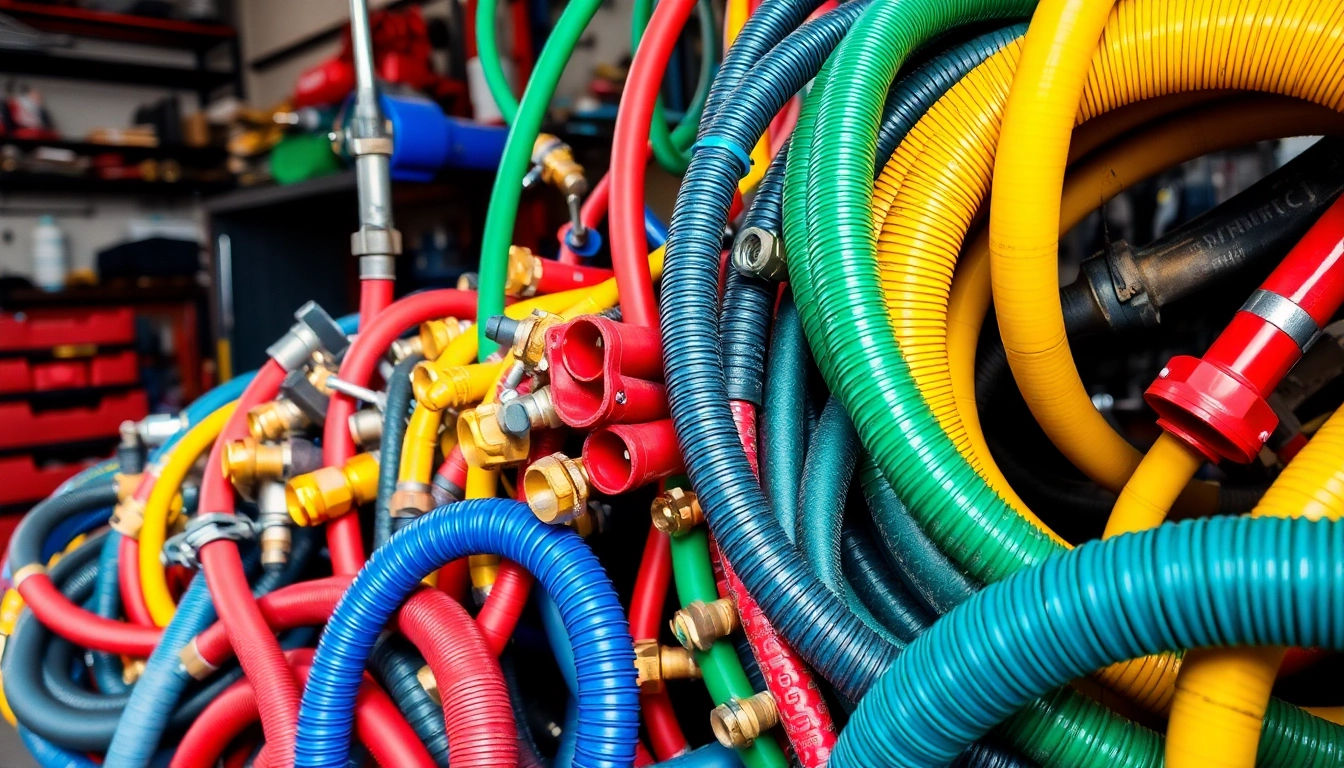

Introduction to Air Hoses and Fittings

In the realm of pneumatic tools, air hoses and fittings serve as the lifeblood of efficiency and effectiveness. These essential components facilitate the smooth transmission of compressed air, ensuring that tools operate at their peak performance. Whether you are a professional tradesperson or a dedicated DIY enthusiast, understanding the intricacies of air hoses and fittings is crucial for any project involving compressed air systems.

Understanding Air Hose Types

Air hoses come in various types, each designed for specific tasks and environmental conditions. The most common types include:

- Rubber Hoses: Known for their durability and flexibility, rubber hoses can handle extreme temperatures but may degrade over time and become heavy.

- Polyurethane Hoses: Lightweight and flexible, polyurethane hoses are popular for their resistance to kinking and abrasion, making them suitable for a variety of applications.

- PVC Hoses: These hoses are less extensible but highly resistant to chemicals and UV light. They are usually more affordable but may not perform as well under high pressure.

- Hybrid Hoses: Combining features of rubber and PVC, hybrid hoses are growing in popularity due to their flexibility, durability, and lightweight nature.

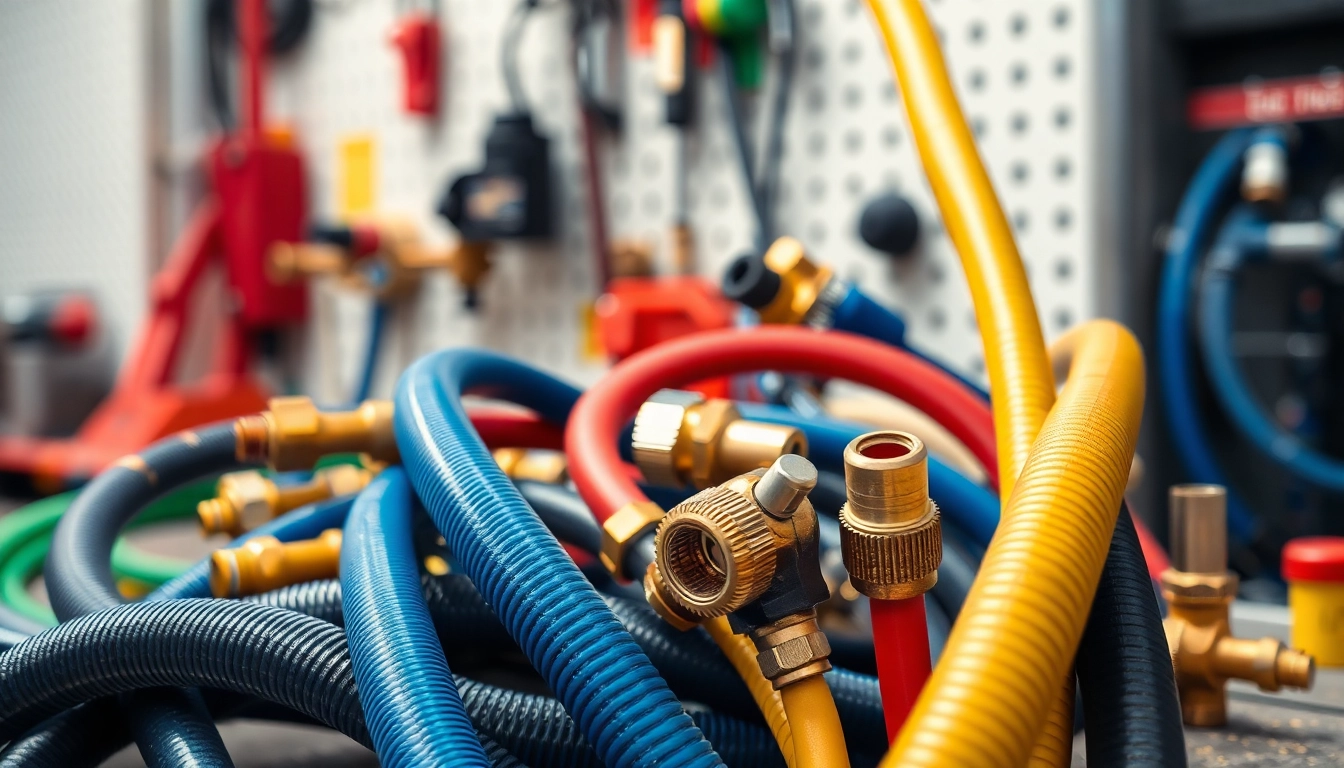

Common Fittings and Their Uses

Fittings are integral to connecting hoses to air compressors and tools. Understanding the various types of fittings is essential for creating a reliable pneumatic system. Some common types include:

- Barbed Fittings: Ideal for connecting hoses to tubing, they create a secure grip but require clamps for added security.

- Quick Connect Couplings: Designed for easy attachment and detachment of hoses, these fittings are incredibly convenient, allowing users to switch tools quickly.

- NPT (National Pipe Thread) Fittings: These are tapered fittings that provide a tight seal and are commonly used with air compressors.

Benefits of Quality Air Hose Systems

Investing in high-quality air hoses and fittings offers numerous benefits:

- Improved Safety: Quality hoses reduce the risk of leaks and bursts, minimizing potential hazards.

- Enhanced Efficiency: Properly working fittings and hoses ensure minimal pressure drop, leading to optimized tool performance.

- Longer Lifespan: Durable materials withstand wear and tear, extending the life of your air hose systems and reducing replacement costs.

Essential Features of Air Hoses

Material Choices: Rubber vs. Polyurethane

The choice of material significantly impacts an air hose’s performance. Rubber hoses offer superior flexibility and can handle hot air, which is ideal for various industrial applications. However, they can be heavy and may crack over time. On the other hand, polyurethane hoses, while lighter and resistant to kinks, are less effective under extreme temperature fluctuations.

Hose Sizes and Compatibility Considerations

Air hoses come in different diameters, typically ranging from 1/4 to 1-inch sizes. It is important to choose a hose size that matches the output of your air compressor and the requirements of your tools. A hose that is too small may restrict airflow, while one that is too large can lead to unnecessary weight and bulk. Additionally, ensure that the fittings are compatible with both your compressor and the tools you intend to use.

Key Performance Metrics to Evaluate

When assessing air hoses and fittings, consider these performance metrics:

- Pressure Rating: Each hose is rated for a maximum pressure. Exceeding this limit can lead to rupture and failure.

- Temperature Range: Depending on the environment, hoses should withstand various temperature extremes without losing integrity.

- Flow Rate: The flow rate determines the amount of air delivered to tools and equipment. Higher flow rates generally mean better performance.

Choosing the Right Air Fittings

Mechanical vs. Quick Connect Couplings

Choosing between mechanical and quick connect couplings depends on the required application. Mechanical couplings generally provide a stronger connection and are more suitable for high-pressure situations. However, quick connect couplings offer unparalleled convenience, allowing users to easily swap connections without the need for tools.

Importance of Thread Types in Air Fittings

Understanding thread types is key to ensuring compatibility. NPT is the most common type of thread for air hose fittings, but there are also British Standard Pipe (BSP) threads. Using mismatched threads can result in leaks and system failure.

How to Obtain a Secure Seal with Air Fittings

Achieving a secure seal involves the proper use of thread sealant tape and ensuring that fittings are joined tightly. Over-tightening can damage the threads, while under-tightening may allow air leaks. Always check for leaks after assembly by applying soapy water to the joints and looking for bubbling.

Maintenance and Care for Air Hoses and Fittings

Best Practices for Longevity

Maintenance is vital for extending the life of air hoses and fittings. Here are some best practices:

- Avoid Overstretching: Always ensure hoses are placed properly to prevent stretching beyond their rated length.

- Regular Inspections: Frequently check for any signs of wear, cracking, or leaks and replace damaged components immediately.

- Proper Storage: Store hoses coiled and away from direct sunlight to prevent UV damage and kinks.

Identifying Wear and Tear

Common signs of wear include visible cracks on the hose surface, frayed fittings, and decreased flexibility. Any of these signs warrant replacement to prevent potential failures during operation.

Cleaning and Storage Tips

Cleaning hoses regularly can help maintain their clarity and functionality. Use mild soap and water to clean dirt and grease, and make sure to dry them completely before storing. When storing, avoid placing heavy objects on top of hoses to prevent distortion.

Where to Buy Quality Air Hoses and Fittings

Comparing Online Retailers and Local Suppliers

When shopping for air hoses and fittings, it’s essential to compare various retailers. Online retailers often provide a wider range and competitive pricing, whereas local suppliers may offer immediate availability and personalized assistance. Here’s a look at what you might find:

- Amazon: A vast selection of products, reviews, and competitive pricing.

- Home Improvement Stores: Local availability and often knowledgeable staff.

- Dedicated Tool Suppliers: Specialized selections and potentially better quality items.

Reviewing Customer Feedback and Product Ratings

Before making a purchase, it’s beneficial to review customer feedback. This can provide insights into product performance, durability, and overall satisfaction. Platforms such as Amazon or specialized hardware forums can be particularly useful for understanding user experiences.

Understanding Warranty and Return Policies

Always check the warranty and return policies when purchasing air hoses and fittings. Products with robust warranties indicate higher confidence from manufacturers in their durability. A clear return policy will also help mitigate risks if the purchased items do not meet expectations.