Introduction to the Unimig Viper

What is the Unimig Viper?

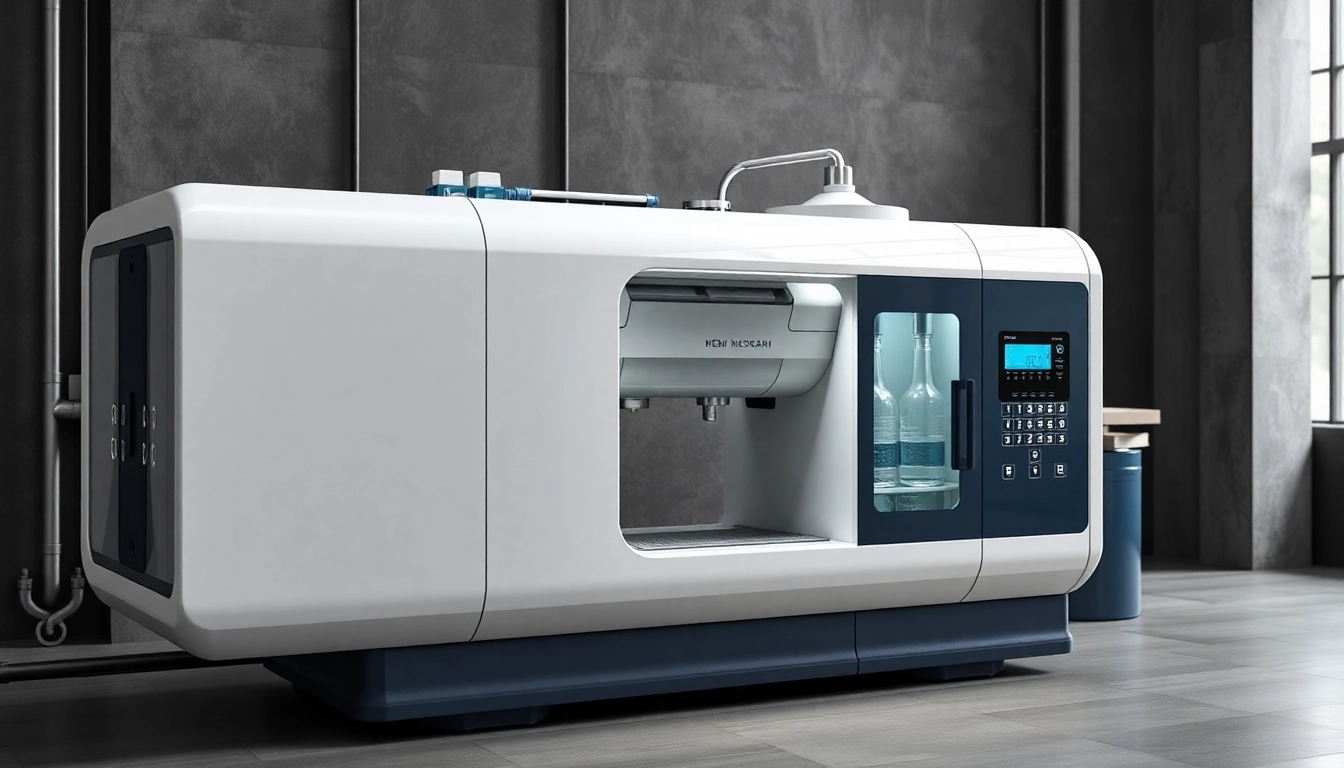

The unimig viper is a versatile and robust welding machine that has carved a niche for itself among both professional welders and hobbyists. Unimig, known for its quality and innovation, has developed the Viper series to meet the demands of various welding applications. The Viper models are designed to perform MIG, TIG, and Stick welding, making them suitable for a wide range of projects—from intricate metal art to structural repairs.

Key Features Overview

The Unimig Viper series boasts a range of features designed to enhance usability and performance. Key attributes include:

- Multi-Process Capability: The Viper can handle MIG, TIG, and Stick welding processes with ease, accommodating a diverse array of materials.

- Portability: Lightweight and compact, these machines are easy to transport, making them ideal for on-site jobs.

- User-Friendly Interface: Intuitive controls and displays simplify operation, even for beginners.

- Advanced Technology: Incorporates synergic MIG technology, optimizing your welding settings automatically for better results.

Target Audience and Applications

The Unimig Viper is aimed at a diverse audience, including DIY enthusiasts, small business owners, and professional welders. Typical applications include:

- Home repairs and maintenance tasks.

- Custom fabrication and model making.

- Automotive repairs and modifications.

- Metal arts and hobby projects.

Benefits of Using the Unimig Viper

Multi-Process Capability

The distinct advantage of the Unimig Viper lies in its multi-process capability. With the ability to switch between MIG, TIG, and Stick welding, users can tackle a multitude of projects without the need to invest in multiple machines. This flexibility is especially beneficial for small workshops and DIY enthusiasts who might engage in varied applications.

Portability and Ease of Use

Portability is critical for many welders who need to move their equipment frequently. The Unimig Viper’s lightweight design, combined with its compact dimensions, allows for easy transport. Moreover, the user-friendly interface means that both beginners and seasoned welders can operate the machine effectively without extensive training.

Cost-Effectiveness and Value

With prices typically starting around $999 for models like the Viper Multi 185, this welder is not just versatile but an economical choice. It delivers high performance without the hefty price tag associated with industrial-grade machines, making it an excellent investment for those who require reliability without breaking the bank.

Specifications and Performance

Welding Modes Explained

Understanding the welding modes of the Unimig Viper is essential for maximizing its capabilities. Each mode functions differently:

- MIG Welding: Ideal for welding thin materials, MIG uses a continuously-fed wire and a shielding gas to protect the weld area. It is excellent for projects that require speed and efficiency.

- TIG Welding: This method offers precise control over the weld pool, making it perfect for intricate work such as stainless steel and aluminum welding.

- Stick Welding: Versatile and effective for outdoor applications, Stick welding uses a consumable electrode and does not require external shielding gas, which can be advantageous in windy conditions.

Technical Specs of Unimig Viper Models

The technical specifications can vary between models within the Unimig Viper range, but they typically include:

- Welding Current: 30-180A

- Welding Thickness: Capable of welding materials ranging from 3mm to 10mm thick.

- Wire Feed Speed: Adjustable wire speeds allow for fine-tuning based on the application.

- Voltage: Most models operate on a standard 10A plug, making them accessible in home settings.

Performance Metrics and User Feedback

Performance is often measured in terms of efficiency, finish quality, and ease of use. User feedback on various platforms indicates a general satisfaction with the Unimig Viper’s capabilities:

- Users commonly report strong arc stability and excellent penetration.

- Many appreciate the ease of switching between different welding modes.

- Durability and reliability have also been frequently highlighted, especially in workshop environments.

Comparing Unimig Viper with Other Welders

Unimig Viper vs. Competitors

When comparing the Unimig Viper to other welding machines in the market, a few factors come into play:

- Performance: Competing models may offer more power or additional features, but often at a higher price point.

- Reliability: The Unimig brand reputation for toughness often outshines competitors, especially in smaller machines.

- Support and Warranty: Unimig provides solid customer service and warranties that stand out against rival brands.

Brand Reputation and Trust

Unimig has cultivated a strong reputation in the industry due to its commitment to quality and performance. Many users trust the brand, noting their positive experiences both with the products and the support provided. This trust plays a significant role in purchasing decisions, especially for welders who understand the importance of having reliable equipment.

Welding Applications in Different Industries

Different industries have unique welding requirements, and the Unimig Viper caters to a variety of them:

- Automotive Repair: Capable of handling various types of metals, the Viper is well-suited for automotive welding tasks.

- Construction: Used in structural fittings and repairs.

- Art and Metalwork: Artisans and fabricators utilize the Viper for delicate and intricate designs.

Making the Purchase: Where and How

Choosing the Right Model for Your Needs

When selecting a Unimig Viper model, consider your specific needs. Factors to consider include:

- Type of Welding: Determine which welding processes you will use most frequently.

- Power Requirements: Ensure you have access to the required power supply for your selected model.

- Weight and Portability: If you’re moving your welder often, consider the weight and size.

Where to Buy the Unimig Viper

The Unimig Viper is available through various online and physical retailers, including specialty welding and tool stores. It’s advisable to purchase from authorized dealers to ensure warranty validation and product authenticity. Major online platforms may also offer competitive pricing and package deals.

Tips for First-Time Buyers

For those new to welding or shopping for a welder, here are some useful tips:

- Do Your Research: Understand different models and their features.

- Ask for Demonstrations: If possible, see the machine in action.

- Check Reviews: Look for user experiences and reviews to gauge reliability and performance.

- Consider After-Sales Support: Ensure that you have access to parts and customer service if needed.