What is Machine Vision?

Definition and Core Concepts

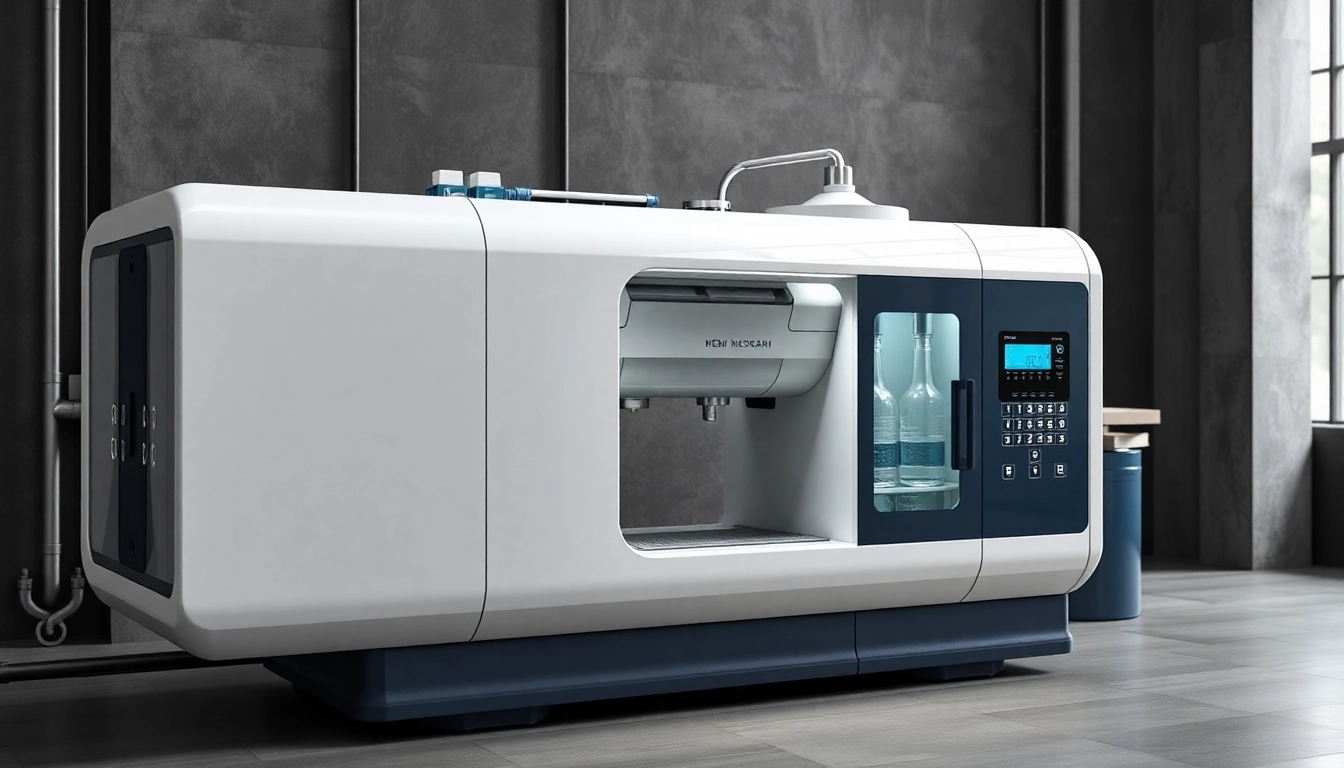

Machine vision is the technology and methods used to provide imaging-based automatic inspection and analysis. It enables machines to interpret visual information, similar to the way humans do with their eyes. In essence, machine vision not only “sees” but also analyzes, recognizes patterns, and makes decisions based on visual input. Utilizing advanced algorithms and computing techniques, machine vision transforms images into actionable data, facilitating automated processes across various industries.

How Machine Vision Works

The functionality of machine vision can be broken down into several critical processes: image acquisition, processing, analysis, and actuation. Initially, the system captures images using cameras or specialized sensors equipped with appropriate optics. The captured images are subsequently transformed from analog to digital format using analog-to-digital converters. Following this, software algorithms process these images, extracting relevant features and analyzing them for further interpretation.

After processing, machine vision systems evaluate the visual data against predefined criteria or learnings derived from historical datasets. Any detected discrepancies, such as defects, can then trigger pre-defined actions, such as sorting or adjusting the product assembly line. This closed-loop feedback mechanism allows for continuous monitoring and improvement of manufacturing processes.

Key Technologies Used

Machine vision systems incorporate a variety of technologies that work in unity to deliver precise and effective results. These include:

- Cameras and Sensors: High-resolution cameras, including 1D, 2D, and 3D sensors, capture visual data across varying applications, from assembly lines to quality control systems.

- Illumination: Proper lighting is essential in machine vision. Various illumination techniques, such as backlighting, dome lighting, and structured lighting, enhance the quality of the images captured, improving accuracy in defect detection.

- Computer Vision Software: Complex algorithms and software solutions process the captured images, utilizing techniques like pattern recognition and deep learning to analyze visual data.

- Processing Hardware: High-performance computing hardware is required for real-time image processing and intricate analyses, managing vast amounts of data efficiently.

Applications of Machine Vision

Quality Control and Inspection

Quality control is one of the most significant applications of machine vision. In manufacturing, it automates the inspection process by ensuring that each product meets the specified quality standards. Machine vision systems can detect defects, measure dimensions, and verify the uniformity of products at a speed that far exceeds manual inspection.

For instance, in the food packaging industry, machine vision systems can identify improperly sealed packages, ensuring that only products meeting safety and quality standards reach consumers. This capability not only enhances product quality but also reduces waste and recalls.

Automated Assembly Processes

Another essential application of machine vision is in automated assembly processes. By incorporating machine vision, manufacturers can streamline assembly lines, ensuring components are aligned and assembled correctly. This automation mitigates human error and increases production speed.

Advanced systems can guide robots in real-time during the assembly process, analyzing each step to confirm that components fit together correctly. The automotive industry illustrates this application extensively, where machine vision facilitates precise component assembly in the manufacturing of vehicles.

Barcode Reading and Tracking

Barcode reading and tracking have become increasingly vital in logistics and inventory management. Machine vision systems equipped with powerful cameras and recognition software can scan barcodes from various angles and distances, significantly improving the efficiency of tracking products throughout the supply chain.

In warehouses, machine vision helps automate inventory checks, reducing labor costs and minimizing human errors associated with manual data entry. This technology actively supports real-time inventory tracking, enhancing warehouse management efficiency.

Benefits of Implementing Machine Vision

Improved Accuracy and Efficiency

The introduction of machine vision in various industrial applications leads to enhanced accuracy and efficiency. These systems operate consistently without fatigue, fatigue, or distraction, ensuring that visual inspections are conducted at a uniform standard. This reliability significantly reduces the chances of defects slipping through the production process.

Machine vision systems can process and analyze images at incredible speeds, enabling continuous quality checks in manufacturing. For example, they can identify defects in products at a rate of thousands of items per minute, which would be impossible through manual inspection.

Cost Reduction and Labor Savings

Incorporating machine vision technology can lead to significant cost reductions for businesses. While initial setup costs can be high, the long-term savings resulting from reduced labor expenses and decreased errors typically justify the investment.

By automating inspection and assembly processes, companies can reallocate human resources to focus on more complex tasks that require creative problem-solving and strategic thinking, ultimately leading to a more efficient workforce.

Real-time Data Analysis

Machine vision systems provide businesses with real-time analytical capabilities, allowing for swift decision-making based on visual data. This is particularly crucial in dynamic environments where conditions change frequently, and timely insights can lead to immediate corrective actions.

Furthermore, this real-time analysis contributes to continuous improvement efforts, as companies can collect data over time, identifying trends and areas for enhancement. This analytical capability can further drive innovation and lead to the development of new strategies to improve production and quality.

Challenges in Machine Vision Implementation

Technical Limitations and Considerations

Despite the numerous advantages, implementing machine vision systems comes with technical challenges. The selection of appropriate hardware and software must align with specific applications, and inadequate choices can result in performance issues.

Moreover, environmental factors such as lighting conditions and variations in product characteristics can impact the effectiveness of machine vision systems. Businesses should undertake careful planning and testing to ensure that these systems are suited to their operational environments.

Integration with Existing Systems

Integrating machine vision systems into pre-existing workflows can pose significant challenges. Businesses often need to invest in additional infrastructure to support new technologies, making it essential to conduct thorough compatibility assessments before implementation.

Furthermore, staff training is crucial to ensure that employees can effectively operate and maintain these systems, which can prolong the transition period. Businesses should develop comprehensive training programs to ease the integration process and enhance staff readiness.

Common Misconceptions

Several misconceptions surround machine vision technology that can hinder businesses from embracing its advantages. One common misunderstanding is that machine vision is a replacement for human workers. In reality, it complements the human workforce by automating repetitive tasks while allowing workers to focus on higher-level operations.

Another misconception is that machine vision cannot handle variations in products or environments. However, with advancements in deep learning and adaptive algorithms, modern machine vision systems are capable of learning from diverse data sets and adjusting in real-time to different conditions.

Future Trends in Machine Vision

Advancements in AI and Machine Learning

The future of machine vision is closely tied to advancements in artificial intelligence (AI) and machine learning. These technologies enable machine vision systems to evolve beyond predefined criteria. Instead, they can learn from the data they process, continually improving their accuracy and reliability over time.

For example, deep learning techniques allow machine vision systems to better recognize complex patterns and anomalies in visual data. This capability is especially beneficial in sectors such as healthcare, where accurate diagnostics can improve patient outcomes significantly.

The Rise of 3D Machine Vision

As industries continue to seek more precise automation, the demand for 3D machine vision systems is on the rise. These systems provide deeper insights into the spatial characteristics of objects, enabling accurate measurements and analyses in complex environments.

In sectors such as robotics, logistics, and quality control, 3D machine vision facilitates more advanced applications, from robot navigation in warehouse environments to intricate assembly tasks requiring precise alignment and positioning.

Industry-Specific Innovations

Different industries are continuously innovating the applications of machine vision tailored to their specific needs. In the automotive sector, for instance, enhancements in machine vision are paving the way for advanced driver-assist systems (ADAS) and autonomous vehicle development. In pharmaceuticals, machine vision is revolutionizing the tracking of products from production through distribution by offering enhanced traceability and compliance with regulations.

As businesses uncover unique challenges and opportunities in their respective markets, machine vision technology will adapt to provide customized solutions that drive efficiency, quality, and output.