Understanding Air Hoses and Fittings

What are Air Hoses and Fittings?

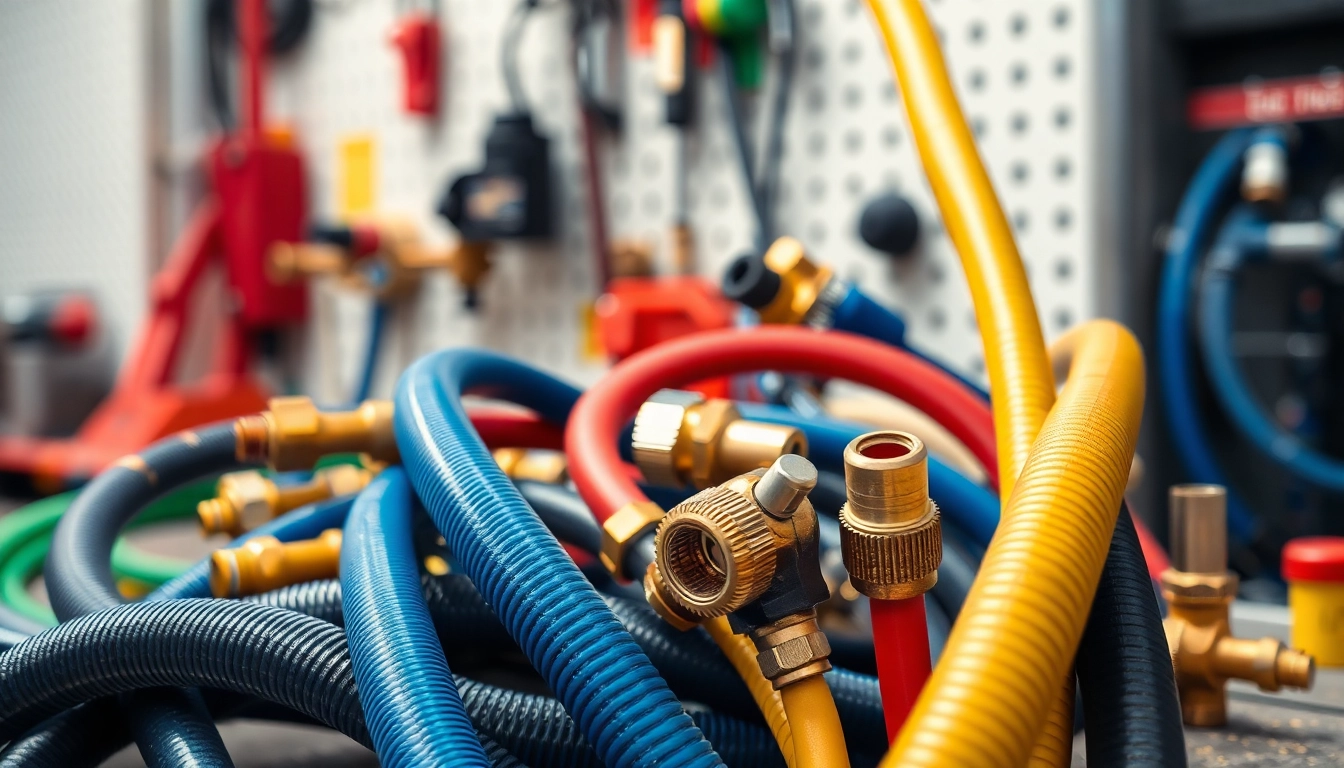

Air hoses and fittings are essential components within pneumatic systems, integral to the operation of air-powered tools and equipment. These components ensure a reliable flow of compressed air from a source, such as an air compressor, to the pneumatic tools that require it for operation. Air hoses transport the air while fittings, which include couplers, adapters, and connectors, facilitate secure connections between hoses and tools or other hoses. The selection of appropriate air hoses and fittings significantly influences the performance and efficiency of pneumatic systems.

In hydraulic and overall manufacturing industries, understanding the role and characteristics of air hoses and fittings is critical. They come in various materials and sizes, dictated by factors such as the specific application, the environment in which they will operate, and the pressure levels to be managed. For comprehensive options on air hoses and fittings, it’s essential to consult specialized suppliers or manufacturers who provide detailed specifications and quality assurance.

Types of Air Hoses: Material and Size Variations

Air hoses can be constructed from several materials, each with unique properties, making them suitable for different applications. The most common materials include:

- Rubber: Known for its excellent flexibility and durability, rubber hoses hold well under pressure and are highly resistant to wear and tear. They perform well across various temperatures but may degrade under UV exposure unless specially treated.

- PVC (Polyvinyl Chloride): PVC hoses are lightweight and resistant to moisture, making them a common choice for agricultural and construction applications. However, they may not withstand high temperatures as well as rubber hoses.

- Polyurethane: These hoses are incredibly flexible, lighter than rubber or PVC options, and provide excellent resistance to abrasion and kinking. They are often used in environments where flexibility is a priority and where the hose must navigate around equipment or obstacles.

- Hybrid Materials: Combining features from rubber and PVC, hybrid hoses offer the best of both worlds, balancing flexibility and durability. They are often freeze-resistant and ideal for users who need high-performance without the heft of traditional rubber hoses.

In terms of size, air hoses typically come in diameters ranging from 1/4 inch to 1 inch and can be purchased in various lengths to suit specific needs. The appropriate size depends on the air tools being used and the required air pressure flow.

Common Applications of Air Hoses and Fittings

Air hoses and fittings serve diverse applications across numerous sectors, including:

- Construction: Used in pneumatic nailers, sanders, and other air-powered tools.

- Aerospace: Employed in assembling components and during maintenance services where compressed air supplies various tools.

- Agriculture: For powering irrigation systems and tools like air seeders that help in sowing seeds with efficiency.

- Automotive: Commonly used in workshops for air wrenches, spray paint equipment, and tire inflation equipment.

Selecting the Right Air Hose for Your Needs

Factors to Consider When Choosing Air Hoses

When selecting air hoses, various factors must be considered to ensure optimal performance:

- Application Requirements: Understand the specific requirements of the tools and applications you’ll be using the hose for. Each tool has unique pressure and flow needs that must be met.

- Length: Consider the distance between the air compressor and the tool, as longer hoses may lead to pressure drops. It’s vital to strike a balance between length and practical maneuverability.

- Diameter: The hose’s inner diameter directly affects airflow and pressure. Ensure compatibility with both your compressor and air tools.

- Working Conditions: Assess the working environment, including temperature extremes, exposure to chemicals, and mechanical wear, to select the most suitable material. For instance, a hose exposed to UV and harsh weather may require additional protection.

- Compliance and Safety Standards: Always ensure that the selected air hoses and fittings comply with local safety and industry-specific regulations.

Durability and Flexibility: Material Comparisons

The inherit characteristics of materials used for air hoses greatly influence their durability and flexibility:

Rubber hoses shine in durability with excellent resistance to puncturing and wear, although they can be heavy and less flexible in extreme cold. In contrast, polyurethane materials provide unmatched flexibility, especially in tight spaces, but may wear quicker under abrasive conditions. PVC hoses, while versatile in lightweight applications, may fail under rigorous heavy-duty use. Deciding which characteristic takes precedence will help determine the best material for the necessary application.

Best Practices for Sizing Air Hoses

Proper sizing of air hoses is crucial for efficient operation:

For general tasks: Select a hose size that balances portability and capacity without sacrificing pressure. An air hose typically performs well in the 1/4 to 3/8-inch range for most common tools.

For high-demand applications: Larger diameters (up to 1 inch) may be needed to ensure adequate airflow and mitigate pressure drops over longer distances. Regular assessment of air flow needs is recommended to ensure the right diameter is being utilized based on tool requirements.

Key Fittings for Air Hose Connections

Common Types of Air Hose Fittings Explained

Fittings are critical as they ensure secure connections between hoses and tools. They typically come in several types:

- Couplers: These allow quick and easy connections between hoses and tools without needing to disconnect the entire system.

- Plugs: Usually attached to the tools or equipment, plugs pair with couplers to establish an airtight seal.

- Adapters: Needed when connecting different hose sizes or types, adapters ensure a seamless interface within systems that may have incompatible connections.

- Inline Filters: While not a connection fitting, inline filters are crucial for ensuring that air entering tools is clean, mitigating wear and operational inefficiencies.

How to Identify Compatible Fittings

To ensure secure connections, identifying compatible fittings is essential. Here’s how:

1. Inspect Hose and Tool Specifications: Check manufacturer ratings for both tools and hoses for pressure ratings, sizes, and types of fittings required.

2. Understand the Thread Type: Most fittings come in various thread types such as NPT, BSP, etc. Identifying the thread type will help ensure a proper and secure fit.

3. Measure the Hose ID/OD: Use appropriate measuring tools to accurately ascertain the inner or outer diameter of the hoses to find matching fittings.

4. Know Your Working Conditions: Consider the pressure requirements and operational conditions of your applications before choosing fittings.

Quick Connect vs. Standard Fittings: Pros and Cons

Choosing between quick connect fittings and standard fittings can affect efficiency and ease of use:

Quick Connect Fittings: These allow for easy, one-handed tool changes and are beneficial in dynamic work environments where tools frequently change.

Pros: Quick connect fittings enhance efficiency with rapid connections and disconnections. They often feature safety mechanisms to prevent air leaks.

Cons: These fittings can incur higher costs and may not be as robust as traditional fittings under heavy-duty conditions.

Standard Fittings: These typically require tools for attachment and may provide a more reliable connection under extreme pressure.

Pros: Generally lower cost and more robust than quick connects. They can handle higher pressures and are more common in industrial settings.

Cons: Slower to connect and disconnect, which may hamper workflow in more agile environments.

Maintenance Tips for Maximum Performance

Regular Inspection of Air Hoses and Fittings

Regular maintenance plays a crucial role in prolonging the lifespan of air hoses and fittings:

1. Visual Inspections: Regularly check hoses for signs of wear, such as cracks, abrasions, or bulging sections. Ensure fittings are tight and free from leaks.

2. Pressure Testing: Periodically subject hoses to working pressures to check for leaks or performance deficiencies.

3. Calibration of Tools: Ensure that the tools connected to air hoses are appropriately calibrated to avoid unnecessary stress on hoses and their fittings.

How to Clean and Store Air Hoses Properly

Proper cleaning and storage of air hoses can significantly enhance their longevity:

1. Use Mild Detergents: Clean hoses with water and mild detergents to remove any buildup of oil or dust.

2. Store Hoses in a Cool, Dark Place: Avoid areas where direct sunlight or heat can degrade materials over time.

3. Use Hose Reels: Consider investing in hose reels which can help with organization and minimize wear when hoses are not in use.

Signs That Indicate Replacement is Necessary

Being vigilant for signs of wear can prevent sudden equipment failures:

- Visible Cracks or Cuts: Any indication of wear through visible damage can compromise the hose’s integrity.

- Air Leaks: If air is escaping from connections or along the hose, it may be time for replacement.

- Reduced Performance: If tools are not receiving adequate pressure or air flow is diminished, consider inspecting the hoses for internal blockages or damage.

FAQs: Your Air Hoses and Fittings Questions Answered

How do I know the right size for my air hose fitting?

To determine the right size, a good rule of thumb is to measure the outside diameter of the male threads and subtract 1/4 inch. For quick disconnect fittings, measure the nominal body size.

What material is best for air hoses in different environments?

In general:

- Rubber: Best for heavy-duty and outdoor applications requiring high durability.

- PVC: Suitable for lighter-use situations indoors where maneuverability is key.

- Polyurethane: Ideal for flexibility in various environments, although performance decreases in extreme heat.

Are there specific maintenance routines for air hoses and fittings?

Yes, maintenance routines should include regular inspections, appropriate cleaning, and proper storage. Creating a routine schedule for these assessments is key to maintaining the longevity of your air hoses and fittings.